A Medley of Local Mushroom Growers

Fungus Among Us

With spring around the corner, visions of once again chopping and sauteing a broader swath of nature’s bounty have begun to dance furtively into the daydreams of Milwaukee chefs and home cooks alike. The scramble is on to plan menus around seasonal ingredients that are so frequently the star of a dish after winter’s thaw. Few of these are as captivating as the humble mushroom. Fewer still are those who have spent the winter growing them.

A handful of local mushroom growers are committed to providing a diverse variety of mushrooms both foraged and cultivated, with a keen eye toward quality and affordability.

Mushroom Mike, LLC

Mike Jozwik’s burgeoning eight-year-old business, Mushroom Mike, LLC, is an increasingly well-known example of this commitment. An expert forager, Jozwik could forget more about mushrooms and wild plants than most will ever know. He recently began growing them in a newly renovated, customized space in the National Warehouse building in Walker’s Point he affectionately dubs “the ’Shroom Factory.”

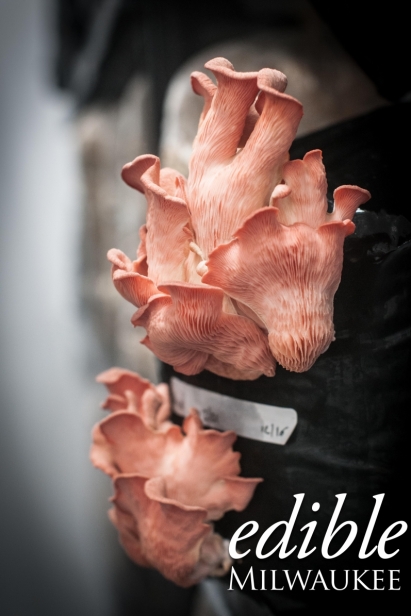

The facility includes a lab, an incubation room and a grow room, where Jozwik produces hen-of-the-woods, king trumpet, lion’s mane, oyster and shiitake mushrooms, plus a half-dozen more species soon to come.

What’s perhaps most unique about Jozwik’s business isn’t that it combines both high-quality cultivated and wild-foraged mushrooms, but that he’s built a broad local, regional and national network of like-minded foragers and suppliers on whom he can call to help meet demand for mushrooms and much more.

“I didn’t get to the point where I’m offering 250-plus products because I really wanted to,” he says. “It’s because chefs constantly want something new and innovative.”

Jozwik’s predilection for mushrooms is inborn. His parents founded the Mycological Society at UW-Parkside, and dad Larry Jozwik helped get the “’Shroom Factory” up and running. The younger Jozwik started foraging while in college and began showing up at kitchen doors, where chefs snapped up what he had to offer.

“All of a sudden it was like, ‘What else can you get me?’” he recalls. Soon came late night phone calls and Facebook messages from chefs who wondered if he could get that special ingredient for a dish they literally dreamed up. He could, and did.

“Offering quality, diversity and affordability are really what got things rocking and rolling,” Jozwik says. “There aren’t a lot of people doing this. I really want people to taste the great local flavors available to them. I want people to be able to eat morels, not have them be some ridiculous ingredient chefs can’t afford to use.”

100% of his sales are direct to restaurants, primarily in Milwaukee, but also in Madison and a few outlying locations. Jozwik intends forage wild greens this year, and hopes to begin offering his mushrooms and sourced products at select farmers markets, including fermented honey, pure maple syrup, and more. This summer, he’ll use a small courtyard next to the building to grow products on demand for chefs—heirloom tomatoes, greens, flowers and other items.

“This is my dream job,” he says. “It’s so cool to be able to go out and pick mushrooms, meet awesome people, make handshake deals with farmers and talk to so many chefs who make such damn good dishes.”

River Valley Ranch & Kitchens

Another local mushroom grower whose size and longevity reflect a passion for fungus is River Valley Ranch & Kitchens. Eric Rose started the farming business with his father, Bill, in 1976. The operation has since become a multifaceted business that employs 50 people, growing and processing 12,000-15,000 pounds of mushrooms each week on its farm, kitchen and store complex in Burlington.

98% of River Valley’s fungi are certified organic white button, portabella and crimini mushrooms, which all grow on the same substrate. A new crop is started every eight days and requires 40 tons of compost and seven weeks to bring to harvest. Rose also grows shiitake, oyster and lion’s mane mushrooms.

In order to utilize and supplement its massive mushroom yield, River Valley offers value-added prepared products like pasta sauces, salsas, dips, pickled vegetables, and hot sauces, most of which feature mushrooms or other produce grown on site, such as asparagus, garlic, shallots, basil, tomatoes, sweet corn, chilies and much more. Also part of the mix are frozen and ready-to-eat items like tamales, vegan veggie burgers and pot pies, as well as grow-your-own mushroom kits.

River Valley employs a full-time chef who devises recipes to utilize the farm’s products. The Rose family also operates a market and cafe in Chicago and is a regular presence at that city’s many farmers markets. In Wisconsin, River Valley Ranch has a presence at a number of farmers markets and a handful of other locations.

“Our processing kitchen consumes about 20% of what we grow, sometimes more. It’s a great way for us to highlight the produce and ensure nothing goes to waste,” Rose says. “Our two retail operations consume about another 10-15% of our fresh mushrooms, the farmers markets consume about 40% and the wholesale market accounts for probably about another 30%.”

The Food Network took notice, featuring the farm’s portabella salsa on its “Food Finds” program. Rose is currently in talks with Whole Foods to get products into its stores.

“Mushroom growing at the level we do is a huge and risky investment. For us and a lot of farms, having a processing kitchen and being able to do value-added products is a critical component of survival. A lot of people are moving in that direction because it affords flexibility that just selling fresh produce doesn’t.”

Sugar Bee Farm

In much the same way Eric Rose identified a complementary way to supplement his existing business, Sugar Bee Farm owner Bryan Simon saw farming mushrooms as a natural extension of the ways he was already working in the dirt—as a landscape contractor, conservationist and part-time farmer of microgreens and worm castings.

Simon owns a former warehouse on South 6th Street that Sugar Bee’s original owners leased to farm mushrooms. After the two sold it to a second owner who ran into problems, Simon bought the business in 2015 and halted production for three months to retool the space in which it operated.

Now back up and running, Sugar Bee primarily produces a medley of four types of oyster mushrooms—grey dove, pohu, pink lady and Italian—for restaurant orders, plus shiitake and lion’s mane mushrooms in smaller quantities for sale at farmers markets. These are supplemented by a variety of microgreens Simon grows on site, as well as honey and honeycomb from nine hives on the building’s green roof. Simon estimates mushroom yield at full capacity will be 200-250 pounds a week.

“We had standing orders from about 20 restaurants, and we’re now getting back into those,” he says, rattling off a who’s who of Milwaukee’ best: Sanford, Lake Park Bistro, Bacchus, Odd Duck, Crazy Water, Goodkind, AP Kitchen, La Merenda and more. At full capacity, about 90% of sales will be to restaurants, with the other 10% to farmers markets.

“We’re able to expand production in the summer months to the five hoop houses we have across the street, which help provide additional vegetables for farmers markets,” Simon says.

An advocate for green spaces, urban farming and environmental sustainability, Simon is executive director of the Energy Exchange Inc., which educates and engages the community on good stewardship of the natural environment through water management, renewable energy, community development and local food systems. The nonprofit is located alongside Sugar Bee in Simon’s building.

Simon led the effort that resulted in a three-mile stretch of South 6th Street between Howard and College Avenues being designated as ‘The Green Corridor” by the City of Milwaukee in 2011. According to Simon, “it’s a testing ground to showcase new and innovative technologies in sustainability” that improve water quality, reduce stormwater runoff, save energy, clean the air and stimulate business and job growth.

“I didn’t expect to be the owner of a mushroom farm, but what I’ve been able to do with microgreens, mushrooms, worm castings, bees … it all helps demonstrate what can be done to benefit the community and the environment.”

Though they each approach mushroom farming from slightly different angles, Jozwik, Rose, and Simon—as well as other local foodcentered businesses like theirs—value craft, quality and integrity every bit as much as profit, ensuring that what ends up on your plate will feel as good as it tastes.